Analysis of Energy Resolution vs. Calorimeter Sampling Fraction

(Based on Slide 20 of DRD6 DD4hep Tutorial, April 2025)

1. Objective

This report summarizes the work completed for Hands-on 3 of the DRD6 DD4hep Tutorial. The goal is to study how the energy resolution of a sampling calorimeter varies with changes in the sampling structure, specifically the thickness of the sensitive material layer within each sampling unit.

The code used for this analysis is available at:

👉 https://github.com/lhprojects/DD4hepTutorials

2. Experimental Setup

- The calorimeter is composed of repeating layers, each consisting of:

- A Silicon sensitive layer (active material)

- A Brass absorber layer (passive material)

- The total thickness of each sampling unit (1 absorber + 1 sensitive layer) is fixed at 10 cm.

- The sensitive layer thickness is varied from 1 cm to 9 cm, while the absorber thickness is reduced accordingly to maintain the 10 cm total per unit.

- These material configurations (especially thick Silicon) are not realistic for actual detector construction, but are used here for illustrative purposes in simulation.

- All setups use the same number of layers and overall detector depth.

- For each configuration, 400 events are simulated using a particle gun shooting monoenergetic electrons (e⁻) directly into the calorimeter.

Geometry Comparison

-

Figure A: Geometry with 1 cm Silicon + 9 cm Brass → mostly absorber

-

Figure B: Geometry with 5 cm Silicon + 5 cm Brass → more sensitive material

3. Analysis Method

- The

.rootfiles are processed using a Python script withpodioandROOT. - For each event, the total energy deposited in the Silicon layers is summed.

- Histograms are created and fitted with a Gaussian to extract:

- Mean deposited energy (

μ) - Standard deviation (

σ)

- Mean deposited energy (

-

The relative energy resolution is calculated as:

σ / μ - A summary plot is generated to show how resolution changes with sensitive layer thickness.

4. Results

4.1 Energy Distributions

-

Figure 1: 1 cm Silicon

-

Figure 2: 5 cm Silicon

-

Figure 3: 9 cm Silicon → shows low-energy tail

4.2 Resolution Trend

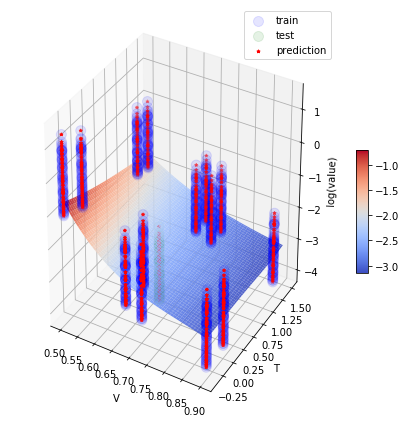

- Figure 4: Relative resolution (

σ / μ) vs. sensitive layer thickness- Resolution generally improves with increasing sensitive thickness

- A slight degradation is observed at 9 cm

5. Discussion

- Increasing the sensitive layer thickness improves energy resolution due to better sampling of electromagnetic showers.

- However, with 9 cm of Silicon, the remaining 1 cm of Brass absorber is insufficient to fully contain the shower.

- This results in energy leakage, which appears as a low-energy tail in the energy distribution and increases the standard deviation (

σ).

6. Conclusion

This simulation study shows that energy resolution in a sampling calorimeter improves with thicker sensitive layers—up to a point. If the absorber becomes too thin, shower containment is compromised, leading to degraded resolution despite increased sensitive material. These results highlight essential trade-offs in calorimeter design and optimization.

Note: This report was initially written by ChatGPT, revised by me, and then refined again with ChatGPT’s assistance.